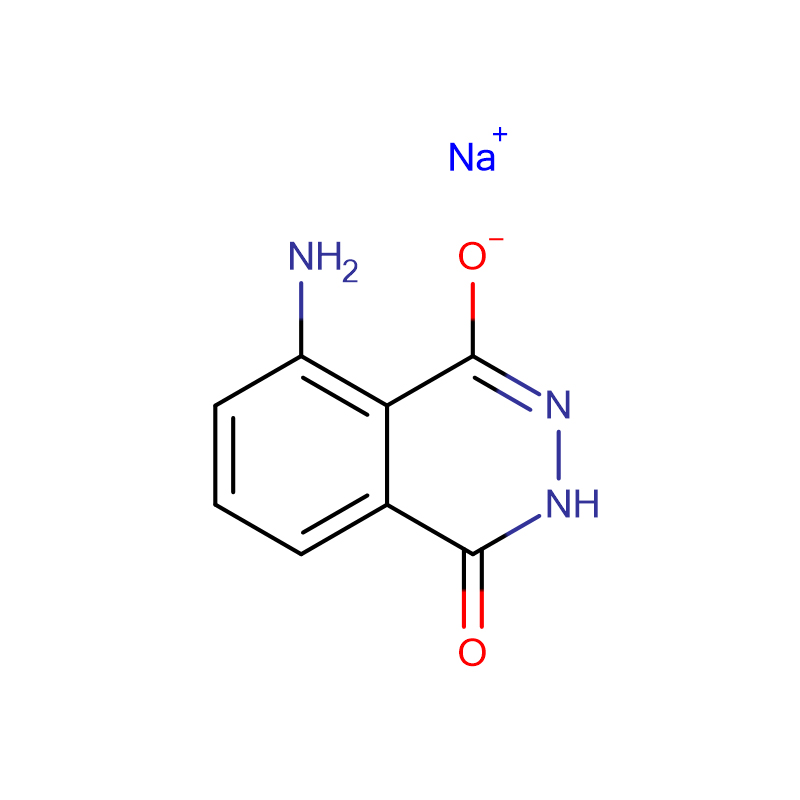

I-AHMT Cas: 1750-12-5 98% Umgubo omhlophe

| Inombolo Yekhathalogu | XD90150 |

| Igama lemveliso | AHMT |

| CAS | 1750-12-5 |

| Ifomula yeemolekyuli | I-C14H20N2O5S |

| Ubunzima beMolekyuli | 146.18 |

| Iinkcukacha zokuGcina | I-Ambient |

| IKhowudi yoMrhumo eHarmonized | 2933990090 |

Ukucaciswa kweMveliso

| Imbonakalo | Umgubo omhlophe |

| uAsay | ≥ 98% |

| Ukuxinana | 2.3100 |

| Indawo yokunyibilika | 228-230 °C (dec.) (lit.) |

| Ukunyibilika | Inyibilika kwiDimethyl sulfoxide.(DMSO) |

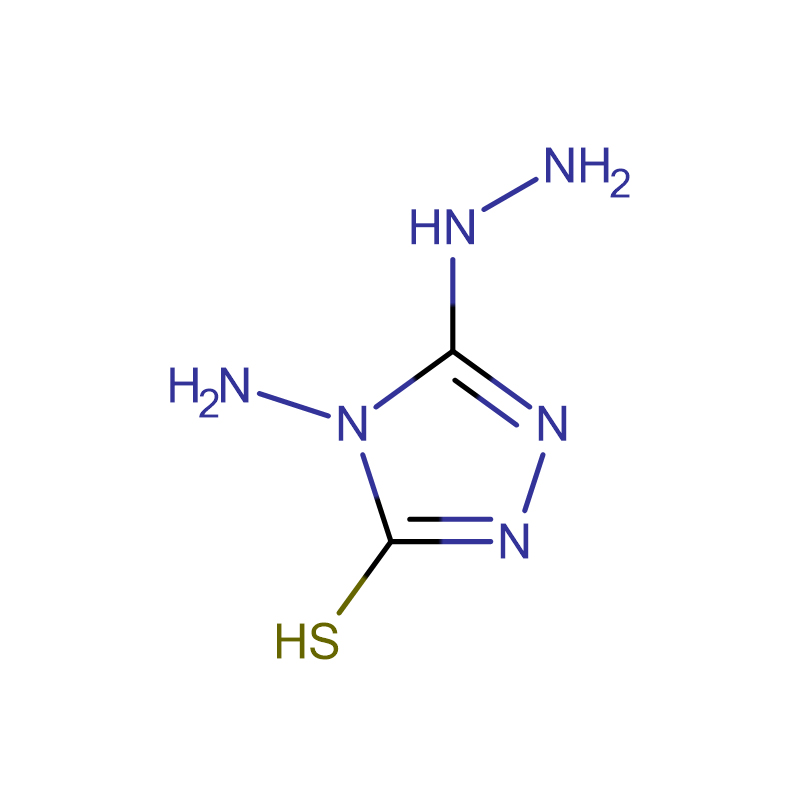

I-reagent ethile yokumisela i-formaldehyde kunye nezinye iikhemikhali ezisebenzayo.Indlela ye-4-amino-3-hydrazino-5-mercapto-1,2,4-triazole (AHMT) ineenkcukacha ezilungileyo kunye nokukhetha, kwaye ingasetyenziselwa inani elikhulu le-aldehydes njenge-acetaldehyde, propionaldehyde, butyraldehyde, kunye ne-phenylacetaldehyde. .Iimeko ezidibeneyo aziphazamisi ukuzimisela, kwaye yindlela ekhethiweyo yokumisela i-formaldehyde emanzini okusela kunye nomthombo wamanzi.

Indlela ye-4-amino-3-hydrazino-5-mercapto-1,2,4-triazole (AHMT) ichaphazeleka kwindawo yebhubhoratri, ukusebenza kwenkqubo yokusabela, ukukhethwa kwezinto kunye ne-reagents kunye nezinye izinto.

Impembelelo yokusingqongileyo ikakhulu kuba i-formaldehyde iyanyibilika emanzini kwaye izinzile emanzini.Ukuba i-concentration ye-formaldehyde emoyeni iphezulu kakhulu, kulula ukuzisa ukuphazamiseka kunye nokungcola kwixabiso elilinganisiweyo le-formaldehyde emanzini.Ngoko ke, xa usebenzisa isisombululo esiqhelekileyo se-formaldehyde kwaye ulungiselela ijika eliqhelekileyo, ixesha lokuvezwa kufuneka lincitshiswe, kwaye iplagi kufuneka ivalwe ngokuqinileyo emva kokusetyenziswa.Ifestile kufuneka ivulwe ukuze kungene umoya phambi kokuphela kovavanyo olunye kunye nokuqala komfuniselo olandelayo.

Impembelelo yenkqubo yokusabela: Emva kokuba i-reagent ivuliwe, kufuneka isetyenziswe ngokukhawuleza, kwaye ingqalelo kufuneka ihlawulwe ukuvala isitywina ngexesha.Isisombululo esilungisiweyo kufuneka sigcinwe kwibhotile emnyama emnyama.Ukongezelela, i-liquid edibeneyo iya kuvelisa ama-bubbles emoyeni ngexesha elifutshane, kwaye umsebenzi kufuneka ushukunyiswe ngokupheleleyo ukuphepha umphumo wokulinganisa ixabiso lokuxhamla liya kuchaphazeleka kwaye lingazinzi.Kufuneka kwakhona kuqatshelwe ukuba ixesha lokungcangcazela, ukuqina, ixesha lokubeka ixesha kunye neemeko zokulinganisa umbala wesampuli engaboniyo, isampuli yereferensi, kunye noluhlu oluqhelekileyo lweetyhubhu ze-colorimetric kufuneka zihambelane.

![N-[[bis[4-(dimethylamino)phenyl]amino]carbonyl] glycine isodiyam ityuwa Emhlophe ukuya kumgubo ongwevu-luhlaza oyikristale](http://cdn.globalso.com/xdbiochems/115871-19-7.jpg)